Aluminum profile extruder industry

For the aluminum profile extruder, our company has launched the AeS-G series hydraulic servo power system with high system pressure, high efficiency, low cost, high standardization, high anti-pollution ability, low noise, and higher stability and reliability, which can realize more efficient operation of extruder (new equipment and stock market), and more power saving and energy saving, greatly reduce operation noise and produce better products.

The special high-pressure non-compensation inside engaged gear oil pump has been used in the highly standardized hydraulic servo system, which greatly improves the service life of the oil pump. With strong market applicability, the whole system is the best solution for domestic performance at present.

Scheme characteristics and advantages

1. Precision:

The speed precision of servo motor can be controlled within 0.1RPM, which improves the quality of finished products and reduces the scrap rate.

2.High efficiency:

The super high response speed of the special Aes-G servo system can significantly reduce the time of auxiliary action, thus reducing the operation cycle and increasing production by 5-15%.

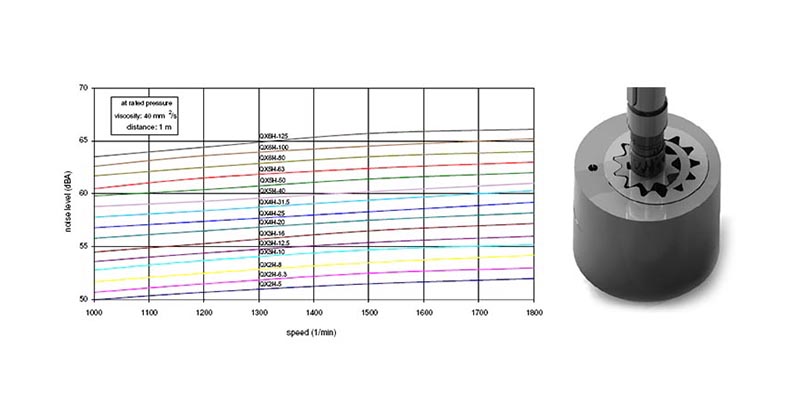

3.Quiet:

The silent internal gear pump has been used in the special servo system of AeS-G extruder, which greatly reduces the noise of the equipment during operation and greatly improves the working environment of the equipment operators.

4.Energy saving:

Servo system “supplies oil on demand”, which avoids overflow loss, thus achieving higher energy saving effect and saving 10-25% of electric energy.

5.Reliability:

The high-pressure inside engaged gear oil pump for the extruder industry has a simple structure, oil film contact (no direct contact between moving parts and high oil resistance, which greatly improves the service life of oil pump. The longest continuous service life of customers has been more than 8 years without problems.

Scheme configuration framework

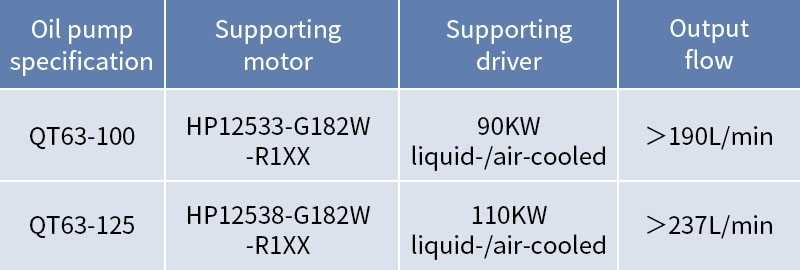

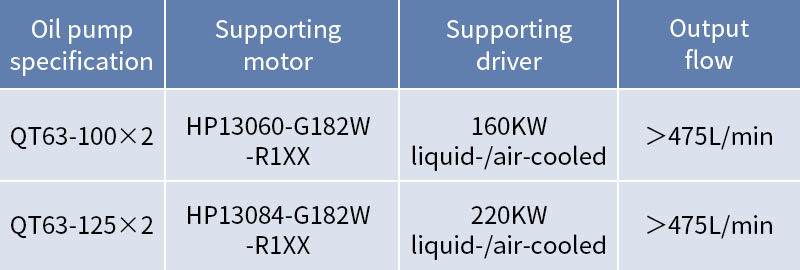

1. Configuration scheme:

High-pressure internal gear pump, high-performance embedded servo motor and full series of liquid-/air-cooled high power servo driver.

2.Advantages:

Haitian’s servo system configuration scheme for the extruder industry (highly standardized system solution and batch stocking improve market response speed and solve many problems such as follow-up after-sales service).

Cases

Case of servo power system transformation of 1000T aluminum profile extruder in a large domestic aluminum processing enterprise.

Before transformation:

After transformation:

Transformation effect:

- The extrusion and auxiliary movements are independently controlled to achieve no overflow loss during the entire working cycle;

- Under the premise of ensuring no increase in installed power, the maximum flow supply and response speed of the system will be improved, and the operation speed of the equipment will be greatly improved, so as to increase production and efficiency;

- The operating noise of the equipment isreduced by at least 15dB to improve the working environment;

- The starting current is greatly reduced, the oil temperature in the oil tank is reduced, the power grid voltageof the plant is stabilized, and the equipment reliability is improved.

Final transformation:

The efficiency of the equipment is increased by 6.3%, the energy consumption of the equipment is saved by 21.7%, and the quality of the finished products is improved, so as to achieve an annual return of more than RMB 70000 for the enterprise!