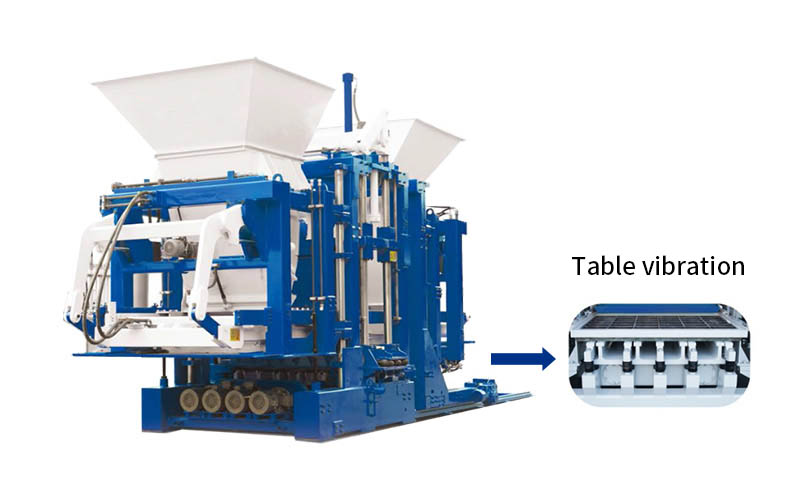

Servo table vibration of brick making machine

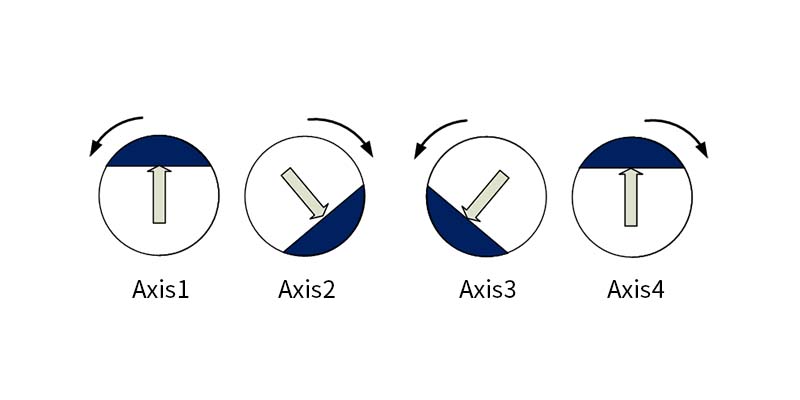

The block forming machine adopts vibratory compaction, that is, depending on the vibration and pressure, the concrete mixture in the mold box is formed and compacted. The pressure and speed of the indenter, the exciting force and frequency of the table vibration and other parameters have an important influence on the performance of the block. At present, characterized by its simple installation, convenient maintenance, short time of vibration initiation and elimination, and convenient adjustment of process parameters, multi-axis servo table vibration is gradually adopted by major block forming machine manufacturers.

characteristics and advantages,

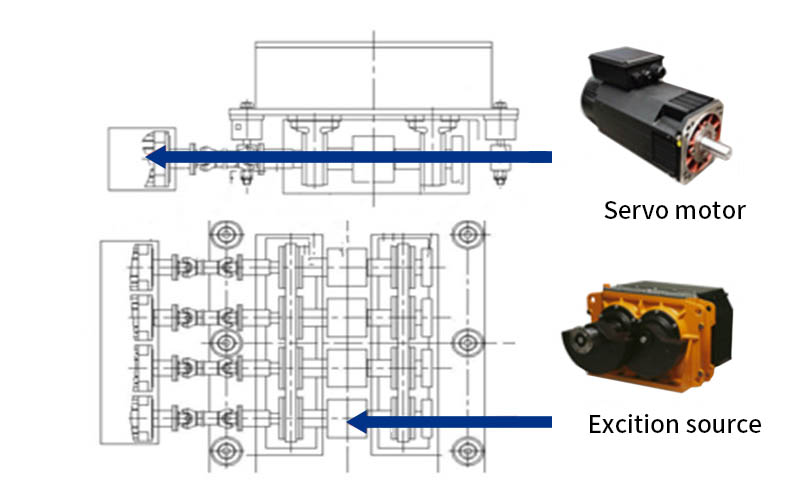

scheme configuration formwork

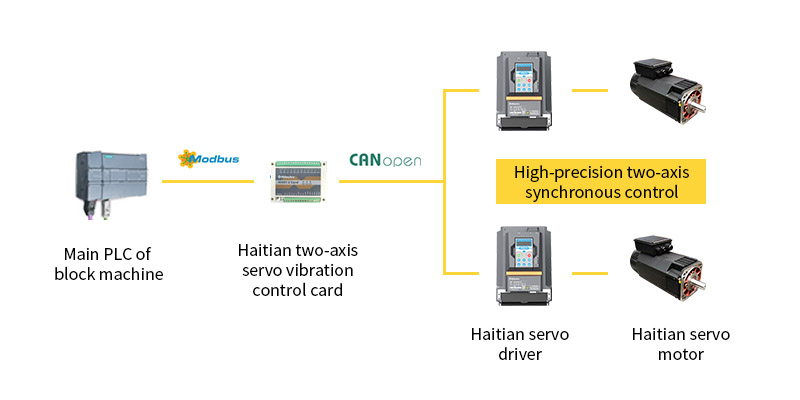

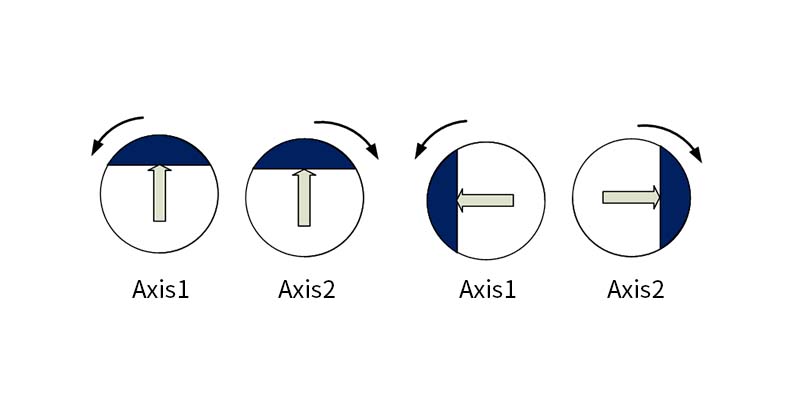

Configuration and characteristics of table vibration control solution for two-axis servo:

- High-precision two-axis synchronization, ±0.3° dual-axis synchronization accuracy, simple equipment structure, no synchronization device between the two axes and convenient maintenance by reducing mechanical structure;

- High cost performance, suitable for large-scale promotion and application.

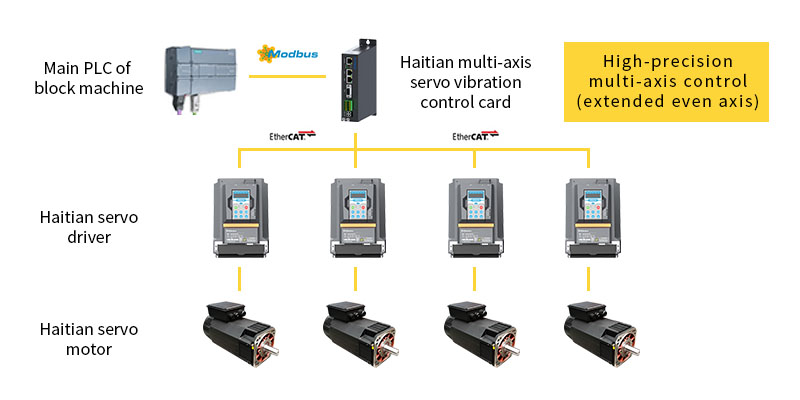

Configuration and characteristics of table vibration control solution for MULTI-axis servo:

- High-precision multi-axis synchronization (four-axis and above);

- The response is fast, and the start-up and vibration elimination time is less than 0.6s for the scheme of variable speed and variable angle, and less than 0.2s for the scheme of full speed and variable angle;

- The energy storage feedback device is equipped, which saves more energy.