Application of rapid packaging machine in injection molding industry

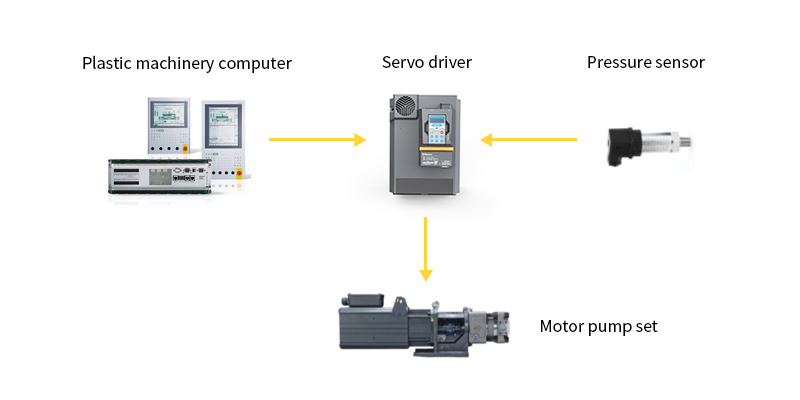

To meet the social requirements of environmental protection and energy saving, plastic packaging containers tend to be thin-walled. Therefore, rapid injection molding and mass production are the main characteristics of thin-walled plastic packaging molding. With the rapid growth of people’s demand for take-outs and express delivery, the demand for special plastics machinery for rapid packaging also begins to grow rapidly. The rapid injection function integrated in the servo driver is specially developed for the injection section, which improves the injection speed and injection stability.

SCHEME Characteristics

- Greatly increase the injection acceleration, where the actual acceleration is greater than 0.5g

- The system response is Fast, the no-load response time (0-2,000rpm) is up to 25ms and the load response time (450-2,000rpm) is up to 54ms

- Add digital quantity control (CANopen) on the basis of compatibility with existing analog control to realize free switching and distribution of master, slave and linkage

|

Recommended Type |

|||

| Sumitomo Oil Pump | Hilectro Motor | Hi Drive | Pressure rating |

| QT62-100F | HP11814-G152F | 37KW | 140KG |

| QT62-125F | HP11814-G182F | 45KW | |

| QT8N-160F | HP12525-G182F | 45KW | |

| QT8N-200F | HP12525-G182F | 55KW | |

| QT6N-125F | HP12521-G182F | 45KW | 175KG |

| QT8N-160F | HP12525-G182F | 55KW | |