Hydraulic draw pad

The draw pad is a press supporting device, which is used to compress the edge of the workpiece to prevent the workpiece from wrinkling during stamping. The development of servo-hydraulic pad technology has brought great benefits to the field of automobile manufacturing. Nowadays, the mechanical press is developing in the direction of the large stroke, large tonnage and high speed. The traditional draw device cannot meet the process technology requirements of a deep draw, large tonnage and low vibration of the new press. To adapt to the development of the press, the precise CNC technology and hydraulic pressure are integrated to get a new type of CNC hydraulic draw pad. The functional characteristics of the CNC hydraulic draw pad can make the press produce more stamping times, better stamping quality and less stamping noise.

Characteristics and Advantages

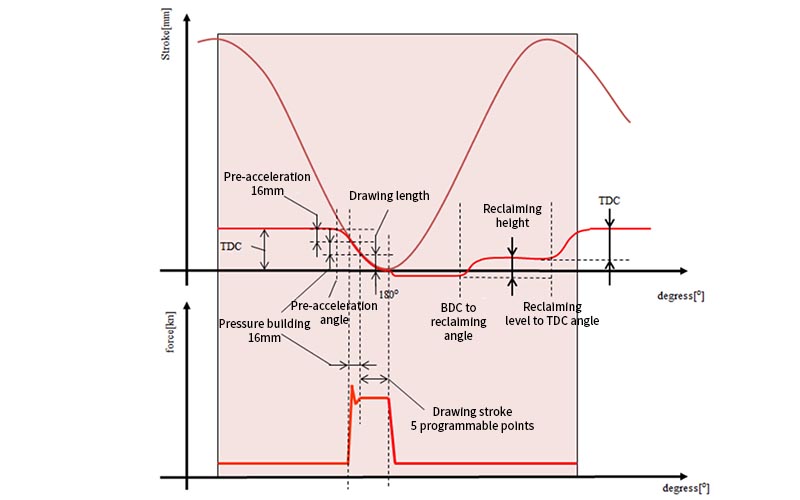

- The hydraulic pad is used for pre-acceleration, but it is possible to choose to turn pre-acceleration on or off, and automatically calculate the starting point

- Establish a smooth drawing force during the drawing process to avoid wrinkles;

- Hydraulic pad force is set by touch screen according to tonnage and controlled by five sections of pressure, which can provide different drawing force at different positions and improve the drawing limit of sheet metal;

- Achieve infinitely smooth decompression at the end of drawing;

- The hydraulic pad realizes the follow-up lifting mode (optional);

- The ejection position of the hydraulic pad is realized by servo pump control or valve control;

- During the soft landing of the hydraulic pad, in principle, the hydraulic pad moves downward without pressure and slowly falls down by its own weight, and the servo control system tracks and controls the force-displacement in real-time to avoid damage to the hydraulic pad caused by impact

Scheme Configuration Network

Industry Case